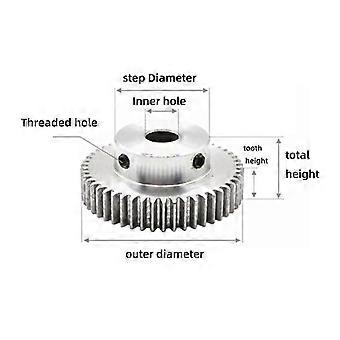

Convex Spur Gear Rack 1 Mod 35T with 10mm Shaft Hole for Motor Drive, Steel 2 Pack

la livraison GRATUITE

Convex Spur Gear Rack 1 Mod 35T with 10mm Shaft Hole for Motor Drive, Steel 2 Pack

- Marque: Unbranded

Convex Spur Gear Rack 1 Mod 35T with 10mm Shaft Hole for Motor Drive, Steel 2 Pack

- Marque: Unbranded

Économisez 30.00 CHF (35%)

Prix de vente recommandé

Politique de retour sur 14 jours

Économisez 30.00 CHF (35%)

Prix de vente recommandé

Politique de retour sur 14 jours

Modes de paiement:

Description

Convex Spur Gear Rack 1 Mod 35T with 10mm Shaft Hole for Motor Drive, Steel 2 Pack

- Marque: Unbranded

- Catégorie: Secteur manufacturier

- Identifiant Fruugo: 440989033-925518030

- EAN: 6221783246483

Livraison & retours

Expédition dans les 24 heures

-

STANDARD: GRATUIT - Livraison entre mar. 06 janvier 2026–jeu. 22 janvier 2026 - GRATUIT

Expédition de Chine.

Nous mettons tout en œuvre pour que les produits que vous commandez vous soient livrés dans leur intégralité et selon vos indications. Néanmoins, si vous recevez une commande incomplète, des articles différents de ceux commandés ou si, pour toute autre raison, la commande ne vous satisfait pas, vous pouvez retourner la commande ou tout produit inclus dans celle-ci et recevoir un remboursement complet des articles. Voir l'intégralité de la politique de retour

Détails de conformité du produit

Veuillez consulter les informations de conformité spécifiques à ce produit décrites ci-dessous.

Les informations suivantes sont fournies par le détaillant tiers indépendant vendant ce produit.

Fabricant:

Les informations suivantes indiquent les coordonnées du fabricant du produit concerné vendu sur Fruugo.

- Mela

- Shenzhen Haiyue Chengfeng Technology Co., Ltd.

- 511 Meilong Avenue, Minzhi Street, Longhua New District

- Changsheng Technology Building 1003B

- Shenzhen

- CN

- 518131

- bxhchen@163.com

- 13717009558

Personne responsable dans l'UE:

Les informations suivantes indiquent les coordonnées de la personne responsable dans l'UE. La personne responsable est l'opérateur économique désigné basé dans l'UE qui est responsable des obligations de conformité relatives au produit concerné vendu dans l'Union européenne.

- Yating He

- E-CrossStu GmbH

- 60329 Frankfurt am Main

- Mainzer Landstr.69

- Frankfurt am Main

- DE

- 60329

- E-CrossStu@web.de

- (+49) 69332967674

- https://kxtvat.kuaxintong.com/